Precision pressure gauge refers to an instrument that u […]

Precision pressure gauge refers to an instrument that uses elastic components as sensitive components to measure and indicate pressure higher than the ambient pressure. Its application is extremely common. It covers almost all industrial processes and scientific research fields. It can be seen everywhere in the fields of heating pipe network, oil and gas transmission, water and gas supply system, vehicle repair and maintenance factories and stores. Especially in the process of industrial process control and technical measurement, because the elastic sensitive element of the mechanical pressure gauge has the characteristics of high mechanical strength and convenient production, the mechanical pressure gauge is more and more widely used.

There are many types of precision pressure gauges. It not only has general (ordinary) pointer indication type, but also digital type; not only conventional type but also special type; not only contact type, but also remote transmission type; not only vibration-resistant type, but also Anti-vibration type; not only diaphragm type, but also corrosion-resistant type. The series of precision pressure gauges is complete. It has not only the conventional series, but also the digital series; not only the ordinary medium application series, but also the special medium application series; not only the switch signal series, but also the remote transmission signal series, etc., all of which are derived from practical needs and have formed The complete series. The specifications and models of the precision pressure gauge are complete, and the structure is perfect. From the nominal diameter, there are Φ40mm, Φ50mm, Φ60mm, Φ75mm, Φ100mm, Φ150mm, Φ200mm, Φ250mm, etc. From the perspective of the installation structure, there are direct installation, embedded installation and convex installation. The embedded installation is divided into radial embedded installation and axial embedded installation. The convex installation also has radial convex installation and axial installation. Convex-mounted points. Direct installation is divided into radial direct installation and axial direct installation. The radial direct installation type is the basic installation type. Generally, when the installation structure type is not specified, it refers to the radial direct installation type.

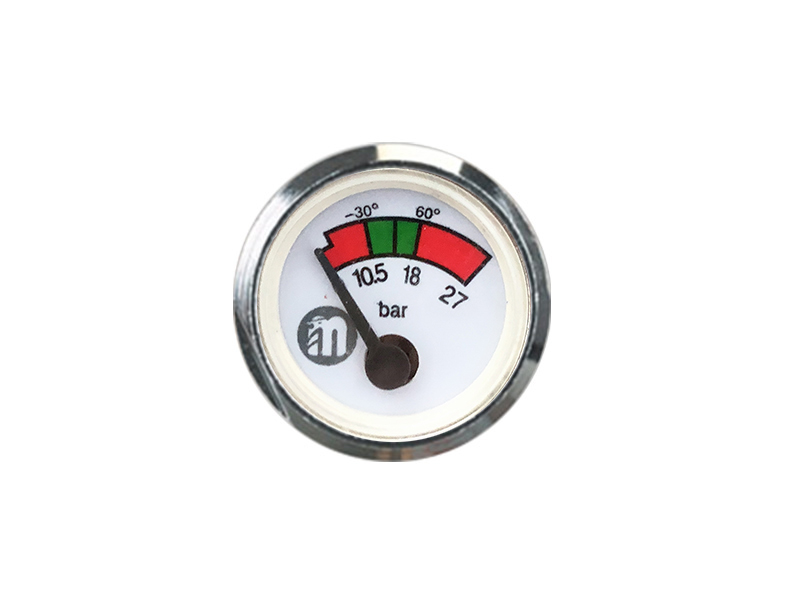

The axial direct mounting type considers the stability of its own support, and is generally only used on pressure gauges with a nominal diameter of less than 150mm. The so-called built-in and convex-mounted pressure gauges are the pressure gauges with edge (mounting ring) we often say. Axial built-in type refers to both axial front side and radial front side. Radial convex type (also called wall-mounted type) refers to the radial rear side pressure gauge. From the perspective of measurement domain and range section, the positive pressure measurement domain is divided into low pressure range section, low pressure range section, medium pressure range section, high pressure range section, and ultra-high pressure range section. In each range section Several measurement ranges (meter range) are subdivided; there are 3 types of negative pressure (vacuum gauge) in the negative pressure measurement domain (vacuum); the pressure gauge of the combined positive and negative pressure is a pressure across the measurement domain table. Its standard name is pressure vacuum gauge, also called vacuum pressure gauge. It can measure not only positive pressure, but also negative pressure. The precision grade classification of precision pressure gauges is very clear. Common accuracy levels are 2.5, 1.6, 0.4, 0.25, 0.05, etc. The accuracy grade should generally be marked on its dial. For some pressure gauges with very low accuracy levels, such as those under level 2.5, some do not need to measure the exact pressure value, but only need to indicate the pressure range, such as the pressure gauge on a fire extinguisher, without marking the accuracy level.