1. Summary The single column working resistance detecto […]

1. Summary

The single column working resistance detector is an instrument for detecting the initial supporting force (working resistance) of a single hydraulic prop. He has the advantages of small size, light weight, portable belt, easy operation, etc., especially the reasonable design of the process structure, which is unmatched in similar products and is favored by operators. The low cost of this product is suitable for the daily carrying inspection of high-end general mining face batch equipment. It is the ideal product for daily inspection of the quality of single hydraulic prop support to ensure efficient and safe production

The single column working resistance detector is mainly composed of a meter head U-shaped card, a measuring body, a thimble and a pressure bar. When in use, first put the U-shaped card on the three-purpose valve, and then insert the body port into the U-shaped card, rotate the U-shaped card to make the body port and the three-purpose valve fit together, and then rotate the pressure lever with a little force. And press down the pressure rod, at this time, the thimble just opens the spherical check valve in the three-purpose valve, so that the liquid pressure in the pillar is introduced into the pressure gauge along the periphery of the thimble in the measuring body, and the initial of the pillar can be read from the meter head. Supporting force (working resistance) value

2. Main technical indicators:

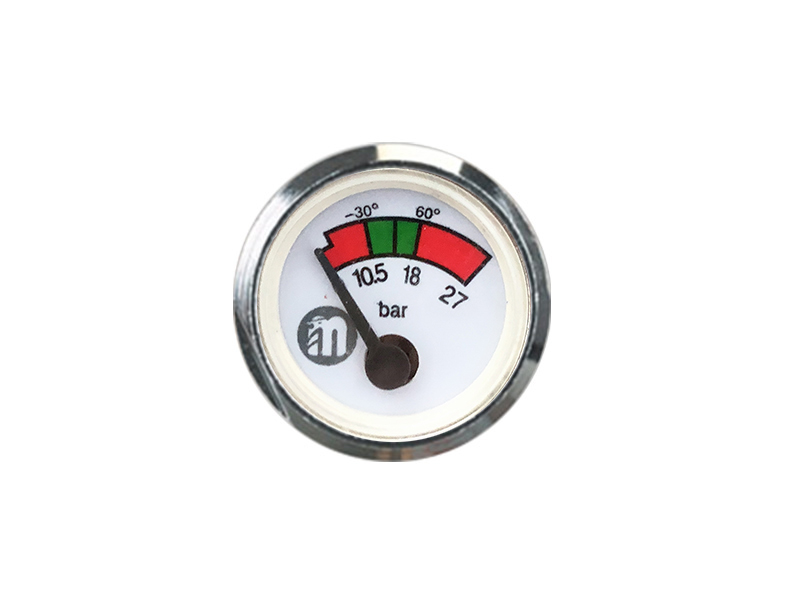

Range: -0.1 ~ 0-60Mpa

Accuracy: 2.5% F / S (1.6% F / S)

Display mode: mechanical

3. Precautions and maintenance

Before use, check whether the rubber gasket in the body of the test body is flat, if it is unevenly placed, it is easy to leak liquid from the body of the body;

The “O” seal ring of the drain system from the rear end of the thimble is damaged and deformed. At this time, the pressure rod can be removed, and the thimble is pulled out from the tail to replace the “O” seal

The head leakage can be tightened with a 6 # small plum wrench

If there is no pressure indication on the gauge head, there are several possibilities: First, the sealing ring is deformed and blocked due to over-tightening of the pressure gauge, which prevents the transmission of liquid pressure. At this time, the lower head and protective cover can be removed to replace the sealing ring. Another possibility is that the thimble is not long enough, or the thimble and the three-purpose valve are not well matched, and the three-purpose valve cannot be opened. In this case, please contact us to replace the thimble. The insufficient thimble length is due to the different specifications of the three-purpose valve. Therefore, when ordering, it is best to specify the specifications of the three-use valve in advance (such as whether it is an anti-flying safety three-use valve, etc.); Until the pressure gauge shows the pressure

Don't use too much force when rotating the lever (only need to apply a little force), so as not to damage the lever

The head and the needle do not return to zero, which does not affect the measurement accuracy. This is mainly due to the expansion force of the liquid in the measurement body.

The thimble should be removed and wiped regularly to prevent corrosion