The selection of pressure gauge should be based on the […]

The selection of pressure gauge should be based on the requirements of pressure measurement in the process of production, combined with other aspects of the situation, to be comprehensively considered and specific analysis, generally consider the following issues.

Selection of instrument type

The selection of instrument type must meet the requirements of process production, and be comprehensively considered according to the physical and chemical properties of the measured medium and the environmental conditions on site. For example, whether remote transmission, recording and alarm are required, special media (such as corrosiveness, high and low temperature, high viscosity, degree of dirt, flammable and explosive performance, etc.), installation location (such as electromagnetic field, vibration, on-site conditions, etc.) are proposed to the instrument Special requirements. In short, the correct choice of instrument type is an important prerequisite for ensuring the normal operation of the instrument and safe production.

For example, the spring tube of a common pressure gauge, when the pressure p ≥ 19.6MPa, mostly choose alloy steel or stainless steel; when the pressure p ≤ 19.6MPa, the material of phosphor bronze or brass can be used. The type of fluid measured is different, and the material of the spring tube used is also different. If the spring tube of the ammonia pressure gauge is made of stainless steel, copper alloy is not allowed. Because ammonia gas is extremely corrosive to copper, it is easily damaged by using a common pressure gauge.

In order to ensure that the connection is tight and leak-proof, when installing, a sealing gasket should be added according to the characteristics of the pressure and the nature of the medium. But when measuring oxygen, grease or organic compound gaskets are strictly prohibited on the gasket to avoid explosion; copper gaskets are prohibited when measuring acetylene.

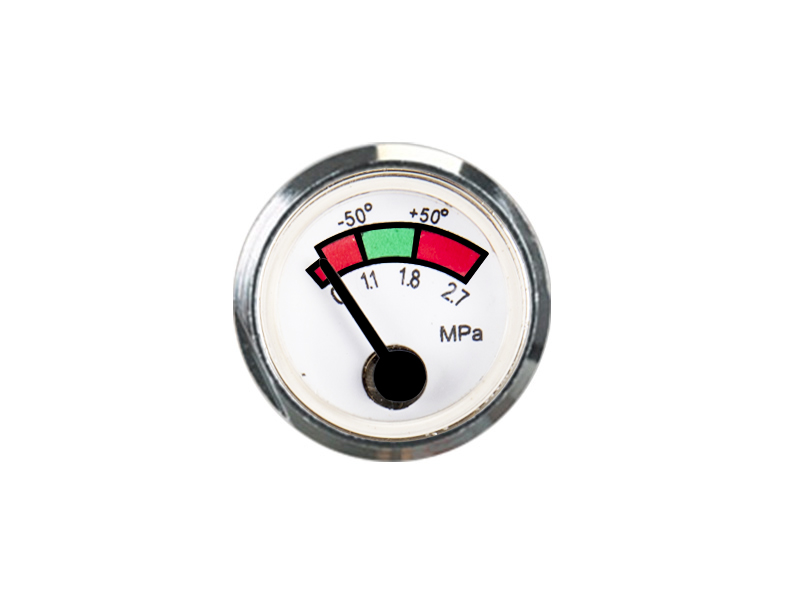

Selection of accuracy level

Determined according to the maximum measurement error allowed in process production. In the case of meeting production requirements, choose a pressure gauge with low accuracy, low cost and durability as much as possible.

Measurement range determination

The measuring range of the pressure gauge should be determined according to the measured pressure in production. In the process of pressure measurement, in order to ensure the measurement accuracy of the pressure gauge, extend the service life of the instrument, and avoid the damage of the elastic element due to excessive force, the upper limit of the pressure gauge should be higher than the maximum pressure value that may occur in the process of production. According to the "Automation Design Technical Regulations", when measuring stable pressure, the normal pressure of the pressure gauge is 1/3 ~ 2/3 of the range, and the highest pressure cannot exceed 3/4 of the range. When measuring pulsating pressure, the normal pressure of the pressure gauge is 1/3 to 1/2 of the range, and the highest pressure cannot exceed 2/3 of the range. When measuring high pressure, the normal pressure of the pressure gauge cannot exceed 3/5 of the measuring range.

After calculating the upper and lower limits of the pressure gauge according to the maximum and minimum values of the measured pressure, this value cannot be used as the measurement range of the pressure gauge. Only round according to the standards formulated by the national competent authority, and select the value in the series as the range of the pressure gauge.